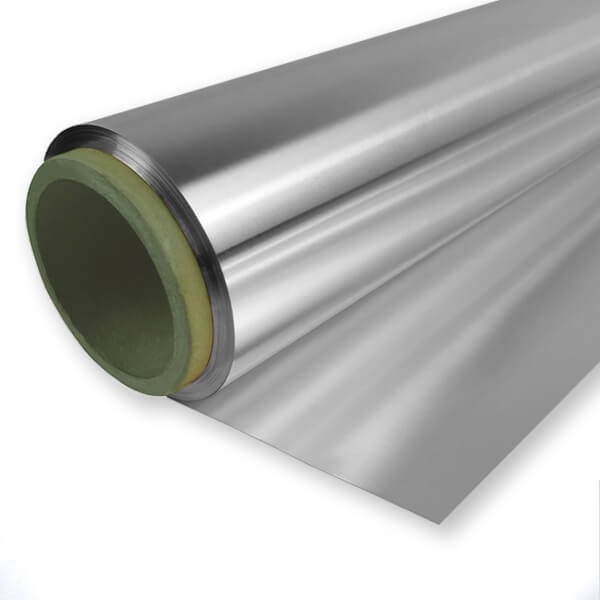

- Order number: 47.10.0015.1000.400

- Note: LxW ca. 300 x 1000 mm

- Info: Special discount on larger quantities!

Due to the addition of 6.0 to 6.5% molybdenum and an increased nickel content of over 24%, this material is extremely corrosion-resistant and suitable for many applications in the food industry as well as environmental and partly suitable for medical technology. The material Alloy 926 is sea water resistant, even at elevated temperatures in heat exchangers and at elevated salt concentrations such as in desalination plants. Since this material is almost non-magnetizable even in the hard-rolled state, it can be used for components that are exposed to strong magnetic fields.

Alloy 926 is known for its exceptional corrosion resistance in aggressive environments. Not only does it resist corrosion from acids, but it also resists other chemical substances such as salt and chlorine found in marine environments. This property makes it an ideal material for applications in chemical processing, shipbuilding and the oil and gas industry. Compared to other grades of stainless steel, it offers superior tensile strength and improved creep resistance at high temperatures. These properties make it an ideal material for automotive applications, where it is used in components such as exhaust systems, catalytic converters and exhaust pipes.

Other examples of use:

- Components in phosphoric acid production

- Components for the bleaching stage in the pulp industry

- Pressure vessels in the temperature range from -196 to 400°; Celsius

- Tanks for storing and transporting aggressive chemical substances

- Building authority approval for components and fasteners in the indoor area of swimming pools (approved by the German Institute for Building Technology, September 1998)

The material 1.4529 is not listed in DIN EN 10 151 as a spring material.

| Material: | Strip Steel |

| Thickness: | 0,15 mm |

| Length: | 1000 mm |

| Width: | 400 mm |

| DIN Material - Name: | X1CrNiMoCuN 25-20-7 |

| Material - Number: | 1.4529 |

| ASTM/AISI (USA): | 926 |

| Surface: | cold-rolled |

| Delivery - State: | weich |

| Norm: | DIN 10204 |

| Magnetisable: | no |

| Tensile Strenght: | 600-900 N/mm² |