- Order number: 33RM.10.0005.1000.600

- Note: LxW ca. 600-630 x 1000 mm

- Info: Special discount on larger quantities!

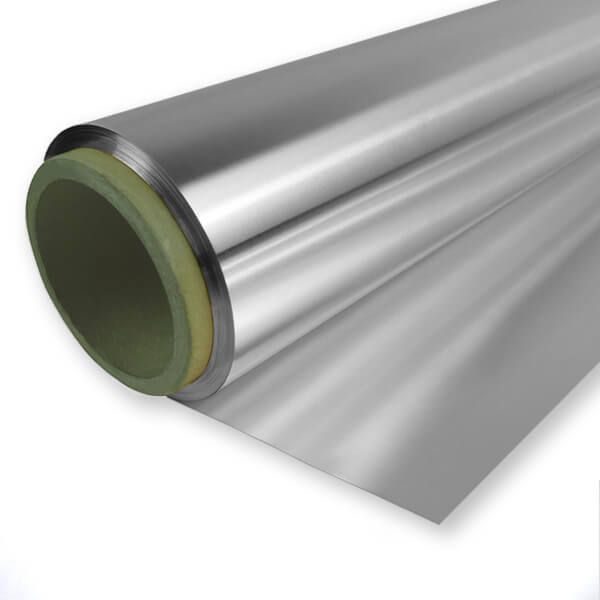

Precision Spring Steel Sheet

Precision sheets or metal foils made of spring steel CrNi - hard steel - 301 are used inter alia. in mechanical engineering as underlay foils, for aligning workpieces in grinding machines, adjusting games (assembly of workpieces) or measuring gap dimensions.

Properties material 301

With this material, high strength is achieved by cold rolling. Compared to material 1.4301, a much higher tensile strength can be achieved.

Therefore, the material is very well suited for stainless precision gauges and shims as well as for stainless springs and parts with higher strength.

Due to the alloy with chrome and nickel, this spring steel has good corrosion resistance. Material 1.4404 should be used in a corrosive environment.

If no special requirements are placed on corrosion, the material 1095 can also be used.

Technical information

The thickness tolerance is defined according to DIN EN 9445 table 1 or T3 (for strength class 15-1700 N / mm²).

Like other austenitic stainless steels, this steel is very easy to weld. However, the heat input at the weld seam can lead to a structural change (which reduces the strength) and, among other things, local corrosion of the weld seam.

With material 301, when bending or bending, make sure that the bends should always run across the rolling direction. When used as a flat spring, the rolling direction must also be observed.

Further technical information on our cold-rolled spring steel 301 can be found in our data sheet.

Further applications / properties:

- Welded endless belts

- conveyor belts

- very easy to etch

- weakly magnetizable

- good corrosion resistance

| Material: | Spring Steel |

| Thickness: | 0,05 mm |

| Length: | 1000 mm |

| Width: | 600 mm |

| DIN Material - Name: | X10CrNi18-8 |

| Material - Number: | 1.4310 |

| ASTM/AISI (USA): | 301 |

| Surface: | cold-rolled |

| Delivery - State: | hard |

| Norm: | DIN 10204 |

| Magnetisable: | weakly |

| Tensile Strenght: | 13-1500 N/mm² |