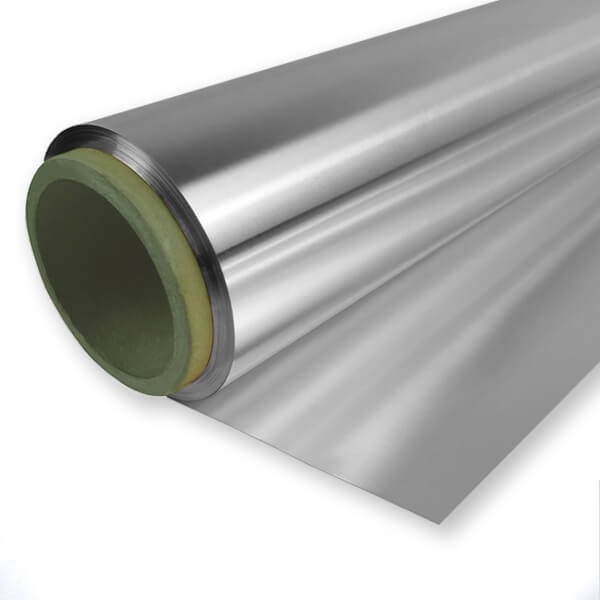

- Order number: 91.10.001.1000.300

- Note: Width about 290-320mm

- Info: Special discount on larger quantities!

Kovar Alloy K - 1.3981 is an alloy mainly composed of iron, nickel and cobalt. Developed in the 1930s, it is known for its remarkable features and versatility. The alloy has low thermal expansion, which means it expands or contracts very little with temperature changes. This makes them ideal for applications that require a stable material that can withstand temperature changes.

Properties and applications of Kovar Alloy K - 1.3981

Kovar Alloy K - 1.3981 is an extremely versatile engineering solution that offers remarkable properties and a wide range of applications in various industries. With its unique combination of thermal expansion properties and excellent mechanical strength, this alloy has become indispensable in electronic and mechanical engineering projects. In this article, we look at the properties and applications of Kovar Alloy K - 1.3981, highlighting its exceptional performance and importance in various fields. Whether you need a reliable material for hermetically sealing electronic packaging or a component that can withstand high temperatures and is corrosion resistant, Kovar Alloy K - 1.3981 can meet your needs. We will look at its thermal stability, low coefficient of thermal expansion, and compatibility with various sealing glasses, making it an ideal choice for the manufacture of solid state devices, vacuum tubes, and others precision instruments. Discover with us the many advantages and applications of Kovar Alloy K - 1.3981 and learn why this material is preferred by engineers and manufacturers worldwide.

Features of Kovar

Kovar Alloy K - 1.3981 exhibits a number of outstanding properties that make it a preferred choice for various applications. One of the outstanding properties of this alloy is its low coefficient of thermal expansion. This means that Kovar Alloy K - 1.3981 expands or contracts minimally with temperature fluctuations. This property is critical in applications where a precise fit of components is required to ensure the performance and functionality of a system. In addition, Kovar Alloy K - 1.3981 offers excellent mechanical strength and high resistance to corrosion and oxidation. These properties make it a reliable material for demanding applications in various industries.

Advantages of using Kovar Alloy K - 1.3981

The use of Kovar Alloy K - 1.3981 offers a multitude of advantages for engineers and manufacturers. The alloy allows for precise manufacturing and assembly of components, resulting in improved performance and functionality of the manufactured systems. In addition, Kovar Alloy K - 1.3981 offers high resistance to corrosion and oxidation, which increases component life and reduces maintenance and replacement costs. The alloy is also compatible with a variety of sealing glasses, further increasing its applicability in various industries. Kovar Alloy K - 1.3981 is a proven solution that has proven itself in a wide range of demanding applications and is valued by engineers for its exceptional properties and versatility.

Alloy K in the medical and healthcare industry

In the medical and healthcare industries, Kovar Alloy K - 1.3981 is valued for its excellent resistance to corrosion and oxidation, as well as its biocompatible properties. The alloy is widely used in the manufacture of medical devices and instruments that require precise manufacturing and high reliability. For example, Kovar Alloy K - 1.3981 is used in implantable medical electronics to make components that can be inserted into the body. The alloy offers excellent long-term stability and ensures the safe and reliable functioning of the medical devices.

Since the material 1.3981 = Alloy K has a similar coefficient of thermal expansion as borosilicate glass and aluminum ceramics, it is ideal for seals between these materials and other components, even over a wide temperature range.

The material is not suitable as a spring material.

| Material: | Nickel alloy |

| Thickness: | 0,10 mm |

| Length: | 1000 mm |

| Width: | 330 mm |

| DIN Material - Name: | FeNi29Co18Mn |

| Alloy: | Alloy K |

| Material - Number: | 1.3981 |

| ASTM/AISI (USA): | K 94610 |

| Surface: | cold-rolled |

| Delivery - State: | geglüht |

| Norm: | DIN 10204 |

| Magnetisable: | yes |

| Tensile Strenght: | 500-600 N/mm² |